Our Focus is on to introduce and equip Kuwaiti Industries with state of the art technology thus saving on their inputs and reducing costs.

‘Waves’ – are exclusive agents and service providers in Kuwait for LINX range of printers – Made in U.K.

Additionally, we supply resin consumables & accessories for various brands of thermal printers, packaging materials, disposables, Packaging Materials, Disposables, accessories in the medical industries , Food industries and other Manufacturing industries with deep expertise, business manners, and communication skills. We also supply obsolete Industrial parts and replacement equivalent parts .

PRODUCTS & SERVICES

LINX Industrial Printers, (Made in U.K) with Accessories & consumables.

LINX PRINTING TECHNOLOGIES are World Class coding & marking specialists with state of the art technology. Waves Kuwait are authorized sole agents, distributors and Service providers in Kuwait giving technical support and service to our valued clients on call.

The new Linx TT Series are designed to deliver a low total cost of ownership and to increase production line output, with an easy to use coding and marking solution.

Consumables for Industrial Printers

Most industrial Printers in Kuwait have very high running cost. We provide Equivalent printer consumables and Inks which are manufactured in USA/Belgium/Japan/Singapore/UK and is relatively less expensive and reliable in the longer run.

Medical Disposables and Consumables.

We Are specialized in Manufacturing Medical Disposables as per the Customers specification and requirement. We generally understand customer requirements and recommend suitable specifications.

We have a Network of Industrial Spare parts Suppliers globally which have surplus stock for Specialized equipment and obsolete equipment. Thus, We have assisted several companies to reduce their downtime by providing relevant equipment and solutions.

Continuous Inkjet Printers

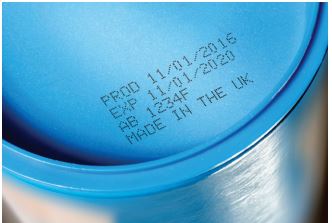

Continuous Ink Jet (CIJ) systems are used to print variable information, such as dates or batch codes, on individual products as they move along the production line – regardless of porosity, size, shape or texture.

Remote printer monitoring and support enables customers to access and control Linx coders anywhere, anytime and enables Linx to provide remote support to keep lines running.

With concealed, easy-to-clean printheads, error-free touch-screen control and simple self-service capability, Linx Printing Technologies provide a cost-effective and efficient solution compared to similar industrial inkjet printers on the market.

Linx 8900 Series

Increasing operational efficiency, made easier than ever with remote connectivity to keep you in control, anytime, anywhere

Applications & Materials

24/7 operations | Barcodes | Batch coding | Data Matrix and QR codes | High-speed production | Retail packaging | Print up to 6 lines

Spend more time coding and increasing your output with a Linx 8900 CIJ printer – the easiest to use Linx printer on the market.

Improve productivity and keep in control of your printer with Linx PrinterNet, remote connectivity enabling you to monitor and control your printer anywhere, anytime.

The Smartphone-inspired screen makes message selection, creation and printer operation faster than ever. Self-service and minimal intervention increases your production uptime. Print onto both primary and secondary packaging with one printer.

Key benefits

- Remote connectivity to access, monitor and control Linx 8900 printers and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- Flexible coder prints up to 6 lines of text, numbers, barcodes and logos

- Simple self-service with up to two years between services – no engineer required

- Quick-change fluid cartridges

- IP55-rated stainless steel enclosure as standard with IP65 option

- Real-time output measurement and line stoppage logs

- Range of ink types and colours for both consumer and industrial marking

- Date freezing for batch printing – ideal for 24/7 operations

- Variable character spacing improves vision system recognition

- Prompts to ensure correct date and text is added to message

- Simple to insert text or logos into messages

Configurations

Linx 8900

Prints 3 lines of code from 1.8mm to 8.8mm high and operates at speeds up to 2.92m/s.

Linx 8910

Prints 3 lines of code up to 20mm high for carton coding/retail-ready packaging, and operates at speeds up to 7.28m/s.

Linx 8920

6-line coding, includes carton code printing up to 20mm, and fast line speed of up to 7.28m/s as standard

Linx 8940

6-line coder designed for the most challenging coding applications, with IP65 rating for reliable operation. Print speeds up to 9.10m/s.

Easy to use for quick code setup

and operation

- Store up to 50 named line settings – for quick retrieval at product changeovers;

settings can be transferred between printers with a USB flash drive• Large, icon-driven high-resolution touch screen, with at-a-glance production-rate visibility• - Customisable top screen, one touch operation for common tasks, on-screen

message prompts for faster, accurate code setup - Simple, one-touch, fluid cartridge refills during printing – no mess, no tools, no mistakes

- Self-service with an on-screen Wizard which guides operators through the service module change process – for a quick, engineer-free service

Reliable coding for longer

- • IP65 rating as standard – for reliable operation in wet or dusty conditions, and no need for an external compressed air supply

- Extended service intervals up to 18,000hrs/ N24 months – code for longer without interventions

• Advanced System Monitoring – internal

monitoring helps to avoid unscheduled

stoppages – reliable coding for longer

• Quick, clean startups every time – robust,

completely sealed printhead, and Autoflush feature ensure continual reliable operation

• Seasonal shutdown mode – printer is ready to print first time, even after extended shutdown, with no need for expensive printer flushing.

Flexible coding with more printing

capabilities

• Linx Printernet enabled – and control of Linx 8900 via a secure, cloud-based

• Code up to six lines of code, 2D

• High speed coding as standard at production line speeds up

• Carton coding option, up to high

• Real-time output on screen – meet OEE targets with the printer ‘On/Off target’; identify patterns overall line downtime with output/downtime reporting feature, and improve your efficiency.

Technical Specifications

Printing capability

Programming features

Physical characteristics

- Up to 6 lines of text, symbols, numbers, barcodes

- Data Matrix and QR codes

- Character height from 1.8mm to 20mm

- Maximum print speeds of up to 9.10m/s

- Carton coding option with character height up to 20mm

- Rotated character (‘tower’) printing

- Screen with icons, drag-and-drop field positioning, and zoom function for longer messages

- Custom date and time editor to create different date formats as required

- USB port for copy and back-up of message and printer settings, and for easy transfer of messages between printers, and downloading of output and line stoppage logs

- Message store of up to 1000

- Real-time output measurement on screen

- Output and line stoppage logs

- Screen saver shows real-time on/off target indication

- Customisable top screen for most frequently used features

- 10” colour touch screen

- Stainless steel enclosure

- IP55 (washdown) as standard

- 2m conduit as standard, with 4m and 6m options

- Weight 24kg

- No factory air required

- Ethernet port, with optional RS232 and Parallel I/O ports for easier integration with line equipment

Linx 10

Simple CIJ printer - superior to other entry-level coders, with remote connectivity to keep you in control, anywhere, anytime

Applications & Materials

Any dry substrate | Best-before dates | Batch coding | Slow-medium speed production | Print up to 3 lines

The Linx 10 is an easy to set up and simple to use Continuous Ink Jet printer designed for printing best before dates and batch codes onto slow and medium speed production lines. It prints up to 3 lines of text, symbols and numbers with a print quality superior to other entry-level coders.

Key benefits

- Remote connectivity to access, monitor and control Linx 8900 printers and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- Flexible coder prints up to 6 lines of text, numbers, barcodes and logos

- Simple self-service with up to two years between services – no engineer required

- Quick-change fluid cartridges

- IP55-rated stainless steel enclosure as standard with IP65 option

- Real-time output measurement and line stoppage logs

- Range of ink types and colours for both consumer and industrial marking

- Date freezing for batch printing – ideal for 24/7 operations

- Variable character spacing improves vision system recognition

- Prompts to ensure correct date and text is added to message

- Simple to insert text or logos into messages

Technical Specifications

Printing capability

Programming features

Physical characteristics

- Prints up to 3 lines of text, symbols and numbers

- Bold character printing

- Upper-and lower-case text

- Rotated character (tower) printing

- Variable character height and width

- Code height range from 1.8mm to 8.8mm

- Line speeds up to 2.66m/s

- Choice of MEK-free and MEK base black inks for coding onto most dry products/packaging

- Colour, touch screen with clear icons for code setup and selection

- Live message preview

- Image-based message selection

- Single touch print start, pause and printer shutdown

- Password protected functions with customisable user profiles for secure, mistake-proof operation

- Message store and printer settings back up, copy and restore using USB storage device

- Simple line speed setup wizard, for quick installation onto new lines

- Weighs only 11kg

- Stainless steel enclosure

- IP55 rating (washdown)

- 7” back-lit full colour touch screen with tough polymer cover

- Flexible and durable conduit, solvent resistant

- Mounting options – direct mount onto line, trolley, bench or table

- Carry handle and printhead dock for safe movement between lines

Linx 7900 Series

Specialist CIJ coding solution with low cost of ownership, with remote connectivity to keep you in control, anywhere, anytime

Applications & Materials

Any dry substrate | Barcodes | Batch coding | Cartons | Data Matrix 2D codes | Advanced production | Print up to 5 lines

The Linx 7900 is a robust printer suitable for coding onto products in a wide range of industries. A range of automated features increase productivity and reduce code errors – improving your efficiency and lowering total cost of ownership.

Key benefits

- Remote connectivity to access, monitor and control Linx 7900 printers and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- Built in automatic code setup features for quicker, error-free coding

- Service intervals of up to 18 months or 9000 hours

- Prints up to 5 lines of text, graphics, logos and Data Matrix 2D codes

- Remote printer monitor and control with Linx Insight

- Fast mistake-proof refills with the SureFill® system

- Automatic printhead cleaning system ensures trouble-free start

- Accurate record of line output – no more manual logging

- Automatically selects the best message type according to the line speed

Configurations

Linx 7900

Prints up to 5 lines of code on line speeds up to 8.41m/s (for single line of code)

Linx 7900BC

Purpose designed for reliable ink jet coding onto bottles. Unique air knife and printhead system ensures the bottle is dried prior to printing, for good ink adhesion. Prints up to 5 lines of code.

Linx 7900E

Electronic marking solution prints micro characters from 1.1mm high, plus ‘tower’ printing, with a specialist ink free from chromium and halogens. Prints up to 4 lines of code.

Linx 7900FG

Purpose-designed for reliable printing with dedicated specialist food grade inks to meet FDA and EU regulations. Prints up to 5 lines of code.

Linx 7900 Solver

Reduced solvent consumption of up to 40%, whilst still delivering maximum reliability. Prints up to 5 lines of code.

Linx 7900 Swift

Narrow font for printing into small areas such as bottle tops, and on line speeds up to 6.83m/s (for single line of code). Prints up 2 lines of code.

Linx 7900 Spectrum

Uses highly pigmented inks for maximum code contrast on dark or coloured surfaces such as rubber and plastic extrusions. Prints up to 5 lines of code.

Technical Specifications

Printing capability

Programming features

Physical characteristics

- Up to 5 lines of text, graphics, logos, barcodes

- Maximum print speed of 8.41m/s (for single line of code)

- Print heights from 1.1mm to 13.8mm

- Data Matrix 2D codes

- Dynamic reverse/invert printing for traversing lines

- Linx Insight remote printer control and status view

- Simple menu-driven WYSIWYG message creation and editing

- QuickSwitch® Plus message selection and editing using a barcode scanner

- PrintSync automated print format selection

- Print History log

- USB port for copy and back-up of message and printer settings, and for easy transfer of messages between printers

- Curved stainless steel casing with minimal dirt traps

- IP55 (washdown) as standard and IP65 (dust proof) as optional

- Weighs only 21kg

- No factory air required

Thermal Transfer Overprinters

Our range of thermal transfer overprinters (TTO) provide an ideal printing solution onto flexible packaging across a wide variety of industrial applications.

This includes printing onto plastics, film packaging, labels, gloss card, and other flexible materials requiring consistent, error free best before dates, batch codes, barcodes, ingredients, logos and other product information.

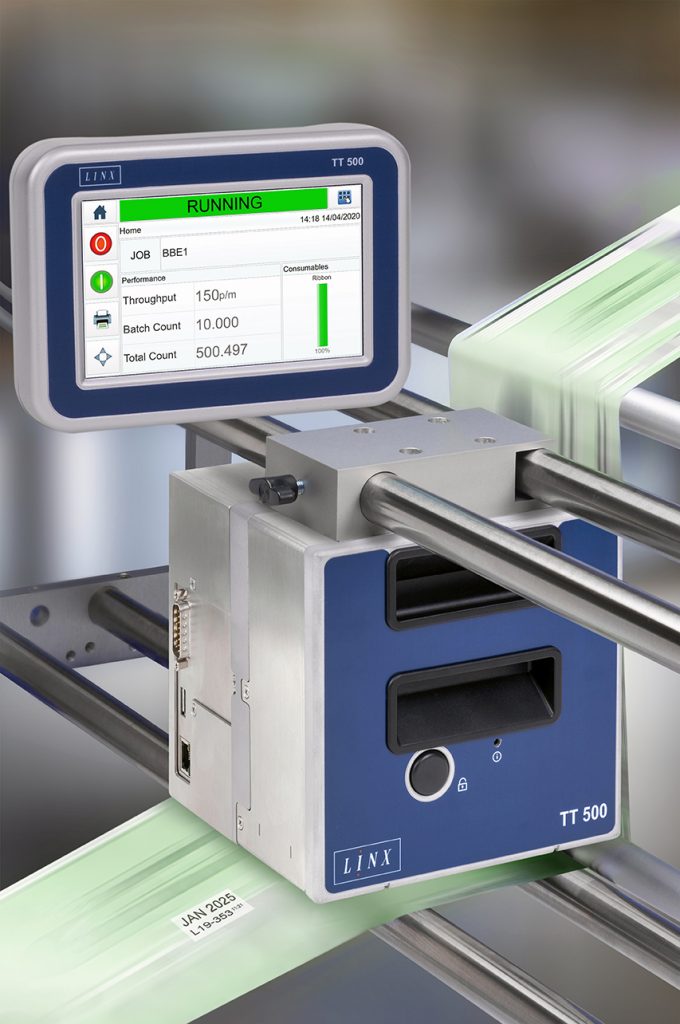

Linx TT 500

Available with a 32mm wide printhead the TT 500 is capable of printing onto flexible packaging and other materials at print rates of up to 150 prints per minute and line speeds of up to 500mm per second

The Linx TT 500 is a simple printer designed for printing onto flexible materials including bags, pouches, labels and flow wrap, ideal when coding areas up to 32mm x 100mm.

Low cost of ownership, increased uptime, easy to use.

Key benefits

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- Simple cassette system minimises errors during ribbon replacements

- Easy to use colour touch screen – fewer errors and hassle-free operation

Technical Specifications

Printing Capabilities

Programming

Physical characteristics

- Ribbon widths:20mm to 33mm

- Print area – intermittent motion mode: up to 32mm (W) x 47mm (L)

- Print area – continuous motion mode: up to 32mm (W) x 100mm (L)

- Maximum throughput: 150 prints per minute

- Maximum ribbon length – 700m

- Print speed – intermittent motion mode: 50mm/sec to 300mm/sec

- Print speed – continuous motion mode: 40mm/sec to 500mm/sec

- Ribbons: Range of types, colours, lengths and widths

- Linx CLARiSOFT message design software

- Barcodes

- Fixed/variable text and numeric fields

- Auto incrementing/ decrementing text, counters and barcodes

- Basic shape drawing

- Flexible date/time formats

- Auto best before date calculation

- Formats for shift coding

- Multiple graphic formats

- …and more

- Operates without compressed air

- Class leading lightened push button open/push to close, simplest ribbon threading cassette system

- Clutchless bi-directional ribbon drive

- 5.0” WVGA (800×480) touch screen graphic user interface

- Universal bracket systems for integrating printer into intermittent and continuous motion packaging machinery

Linx TT 750

Available with a 32mm or 53mm wide printhead the TT 750 is capable of printing onto flexible packaging and other materials at print rates of up to 250 prints per minute and line speeds of up to 750mm per second.

The Linx TT 750 is a simple printer designed for printing onto flexible materials including bags, pouches, labels and flow wrap, ideal when coding areas up to 53mm x 200mm.

Low cost of ownership, increased uptime, easy to use.

Key benefits

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- Simple cassette system minimises errors during ribbon replacements

- Easy to use colour touch screen – fewer errors and hassle-free operation

Technical Specifications

Printing Capabilities

Programming

Physical characteristics

- Ribbon widths – 20mm to 55mm

- Print area – intermittent motion mode: up to 53mm (W) x 75mm (L)

- Print area – continuous motion mode: up to 53mm (W) x 200mm (L)

- Maximum throughput: 250 prints per minute

- Maximum ribbon length – 1200m

- Print speed – intermittent motion mode: 40mm/sec to 750mm/sec

- Print speed – continuous motion mode: 40mm/sec to 750mm/sec

- Ribbons: Range of types, colours, lengths and widths

- Linx CLARiSOFT message design software

- Barcodes

- Fixed/variable text and numeric fields

- Auto incrementing/ decrementing text, counters and barcodes

- Basic shape drawing

- Flexible date/time formats

- Auto best before date calculation

- Formats for shift coding

- Multiple graphic formats

- …and more

- Operates without compressed air

- Class leading lightened push button open/push to close, simplest ribbon threading cassette system

- Clutchless bi-directional ribbon drive

- 8.0” WVGA (800×480) touch screen graphic user interface

- Universal bracket systems for integrating printer into intermittent and continuous motion packaging machinery

Linx TT 1000

Available with a 53mm or 107mm wide printhead the TT 1000 is capable of printing onto flexible packaging and other materials at print rates of up to 700 prints per minute and line speeds of up to 1,000mm per second.

The Linx TT 1000 is a simple printer designed for printing onto flexible materials including bags, pouches, labels and flow wrap, ideal when coding areas up to 107mm x 300mm.

Low cost of ownership, increased uptime, easy to use.

Key benefits

- Operates without compressed air reducing installation and operating costs while maintaining consistent print quality

- Large range of ribbons to better meet your application and production line printing needs

- Optimised ribbon usage with bi-directional stepper motors delivering more prints per ribbon

- Lightweight, simple, push button ribbon cassette system for quick and easy ribbon changes

- Optimal number of user maintainable parts that are easy to replace

- Easy to set and maintain print quality with electronic pressure control

- Simple cassette system minimises errors during ribbon replacements

- Easy to use colour touch screen – fewer errors and hassle-free operation

Technical Specifications

Printing Capabilities

Programming

Physical characteristics

- Ribbon widths: 20mm to 110mm

- Print area – intermittent motion mode: up to 107mm (W) x 75mm (L)

- Print area – continuous motion mode: up to 107mm (W) x 300mm (L)

- Maximum throughput: 700 prints per minute

- Maximum ribbon length – 1200m

- Print speed – intermittent motion mode: 10mm/sec to 800mm/sec

- Print speed – continuous motion mode: 1mm/sec to 1000mm/sec

- Ribbons: Range of types, colours, lengths and widths

- Linx CLARiSOFT message design software

- Barcodes

- Fixed/variable text and numeric fields

- Auto incrementing/ decrementing text, counters and barcodes

- Basic shape drawing

- Flexible date/time formats

- Auto best before date calculation

- Formats for shift coding

- Multiple graphic formats

- …and more

- Operates without compressed air

- Class leading lightened push button open/push to close, simplest ribbon threading cassette system

- Clutchless bi-directional ribbon drive

- 8.0” WVGA (800×480) touch screen graphic user interface

- Universal bracket systems for integrating printer into intermittent and continuous motion packaging machinery

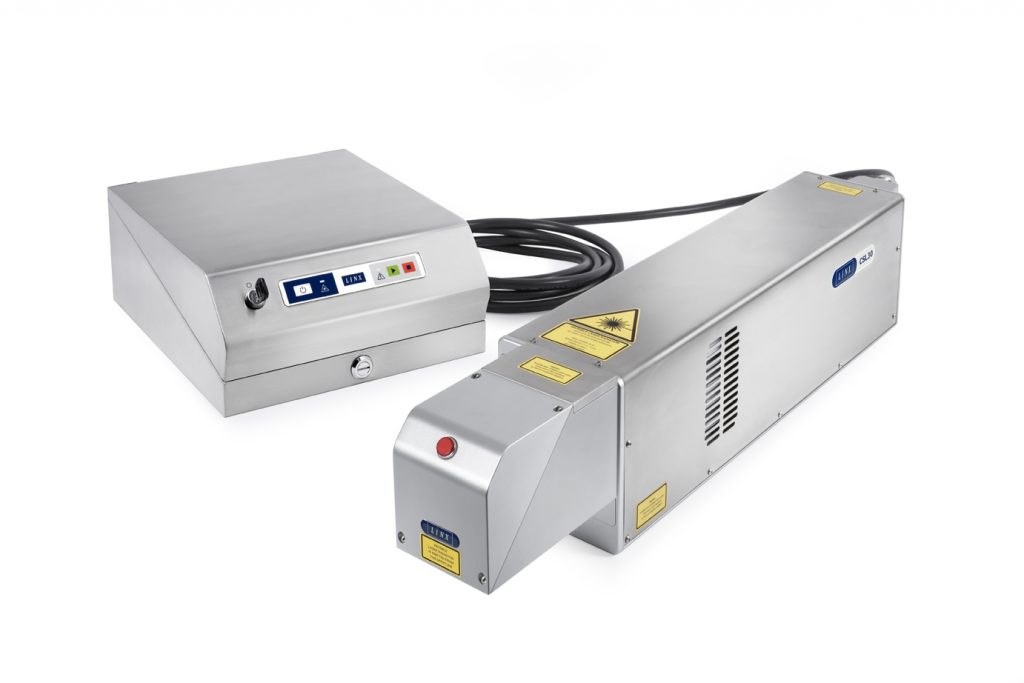

Laser Coder

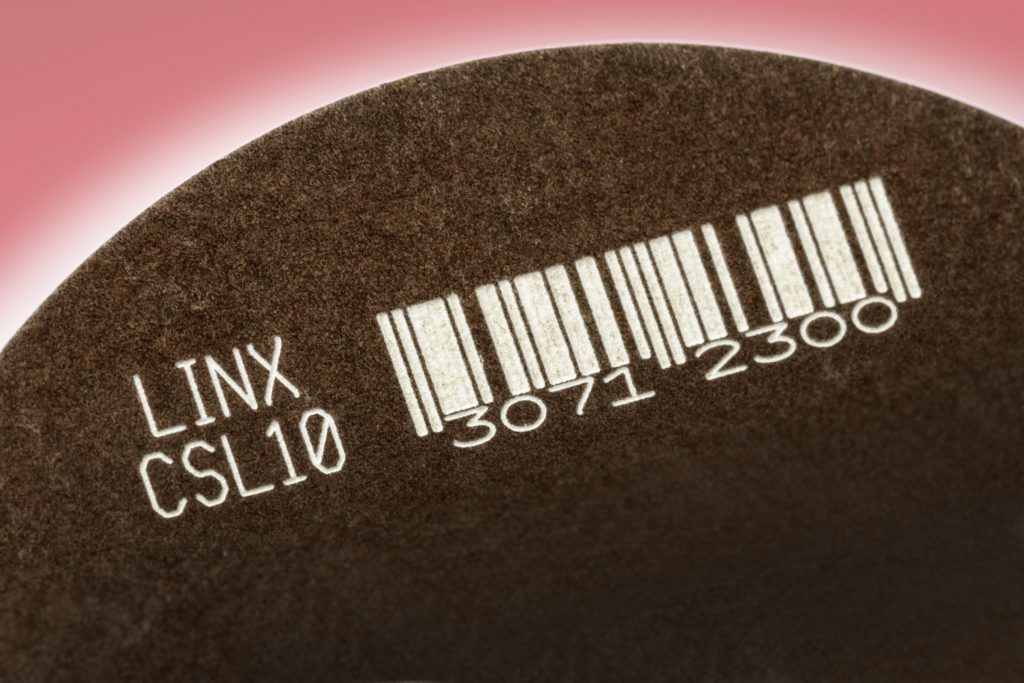

Linx laser marking machines and coding systems are ideal for high print volumes – such as food, drink and pharmaceutical products – while providing permanent traceability.

Improve productivity and keep in control of your Linx CSL laser marking and coding systems with Linx PrinterNet, remote connectivity enabling you to monitor and control your printer anywhere, anytime.

Linx laser coders offer any-orientation coding alongside full touch-screen control, low maintenance costs and zero consumables – providing an affordable and effective solution compared to other products on the market.

Laser Coding and Marking

Key benefits of Laser Coders over other manufacturing printing solutions include:

- Zero consumables

- Full touch-screen control

- Low maintenance

- Any-orientation 3-axis coding

- Static marking capability

- Code logos, barcodes, data matrix & more

Linx laser coders provide an affordable and reliable solution compared to other coding and marking products on the market backed up by our leading product advice and support team

The Best Laser Coder For Your Needs

Choosing the correct laser marking solution for your product is critical, as well as selecting the right type of laser, either fibre or CO2. Linx always recommends that we run sample marking for your product material or substrate based on your line speed to ensure that the correct wattage of laser is selected for your marking application.

As a reputable installer, Linx also provide safety advice for use of lasers in the workplace such us protective guarding and fume extraction depending on your coding substrate.

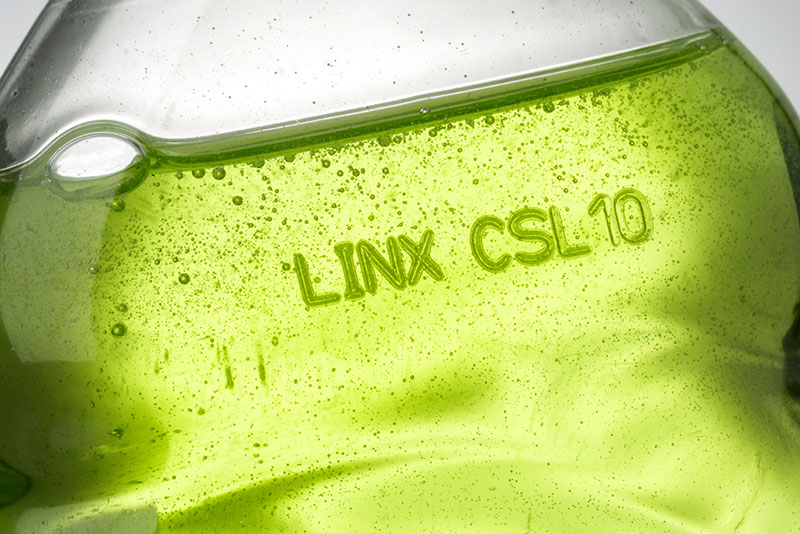

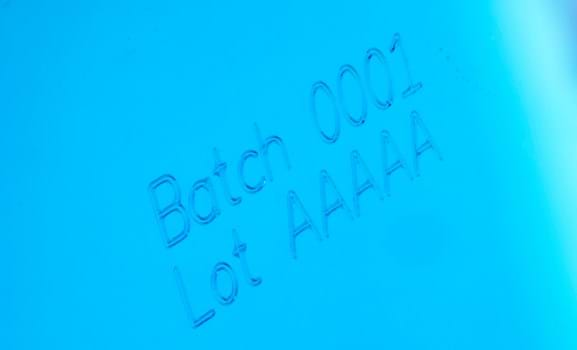

Linx CSL10

10W - Economical yet versatile, with easy installation

Applications & Materials

Broad materials support incl. Glass | Barcodes | Batch coding | Data Matrix & QR codes | Up to 900 m/min | Print unlimited lines of text

The Linx CSL10 is a high specification, 10 W CO2 scribing laser coder. Designed to be economical yet versatile, it is suitable for a wide range of laser marking applications. Produces complex variable codes and dynamic messages, even on high speed lines for quality coding on a wide range of materials. With a detachable marking head and connectors for easy installation.

Key benefits

Easy to use

Meet production targets

Print in more applications

- Easy message creation and management of printing parameters with the large colour LinxVision® Touch Screen, and LinxVision software

- Reduce your coding errors and meet coding regulations with password controls that can restrict access to qualified personnel only

- Easy line integration – detachable marking head with quick disconnect cables

- Multiple beam delivery options allow for coding in any orientation

- Remote connectivity to access, monitor and control Linx CSL laser coders and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- A powerful, four-core processor allows printing of complex messages – including 2d barcodes, QR codes and logos – on fast lines with no compromise on code quality

- Reduce running costs and delays with 45,000* hour tube life – one of the longest on the market

- Service intervals typically twice that of the industry standard

- No expensive factory air for cooling

- Over 20,000 different configurations to economically meet your coding requirements

- Wide web applications for large area coding or multiple lines of products

- Crisp, clear coding on glass, even at high line speeds, with VisiCode®, a unique set of parameters

- Flip, mirror or curve text – easily code onto difficult shapes

*tube life is application dependent

Technical Specifications

Printing capability

- CO2 scribing laser coder

- Line speed – up to 900 m/min (code and substrate dependent)

- Maximum laser output power at lens – 10W

- Lens and head options (range):

- Spot Size 0.09 mm – 1.12 mm

- Marking Field 29 mm x 36 mm – 294 mm x 406 mm

- Mark distance 385 mm

- Number of lines of text – only limited by character size and marking field size

- Character height – up to marking field size

- Print rotation – 0-360°

- Marking head rotation – 0-360°

- Code options: date, time, static text, variable text, serial numbers, alphanumeric, shift codes, increment/decrement (batch count), ID Matrix 2D codes, barcodes, QR codes, graphics and logos, Julian dates, custom date and time formats

- Laser tube wavelengths – 10.6 µm or 9.3 µm

- Marking head options – 3 head options available as standard

- Versatile Beam delivery options for easy integration into your production line:

- Down (90°) or Straight (0°) Shooter

- 360° Beam Extension Unit (BEU)

- Variable length Beam Turning Unit (BTU)

- IP rating – IP54 as standard, IP65 option

- Air cooled – not factory air

- Large volume gas tube can last in excess of 45,000* hours

- Laser tube warranty – 2 years

- *Tube life may vary according to application.

Linx CSL30

30W - For high-speed marking of complex codes

Applications & Materials

Variety of materials incl. Glass, Rubber | Barcodes | Batch coding | Data Matrix, QR and dot codes | Up to 900 m/min | Print unlimited lines of text

The Linx CSL30 laser coder produces sharp codes on fast lines, and even on hard to mark materials such as glass and rubber. It’s been designed to keep up with your coding requirements as they change – line speed, code complexity, or material types – with no additional investment needed.

Key benefits

Easy to use

Meet production targets

Print in more applications

- Easy line integration – detachable marking head with quick disconnect cables

- Multiple beam delivery options allow for coding in any orientation

- Easy message creation and management of printing parameters with the large colour LinxVision® Touch Screen, and LinxVision software

- Reduce your coding errors and meet coding regulations with password controls that can restrict access to qualified personnel only

- Remote connectivity to access, monitor and control Linx CSL laser coders and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- Reduce running costs and delays with 45,000* hour tube life – one of the longest on the market

- Service intervals typically twice that of the industry standard

- A powerful, four-core processor allows printing of complex messages – including 2d barcodes, QR codes and logos – on fast lines with no compromise on code quality

- No expensive factory air for cooling

- Crisp, clear coding on glass, even at high line speeds, with VisiCode®, a unique set of parameters

- Flip, mirror or curve text – easily code onto difficult shapes

- Over 20,000 different configurations to economically meet your coding requirements

- Wide web applications for large area coding or multiple lines of products

*tube life is application dependent

Technical Specifications

Coding and marking capability

- CO2 scribing laser coder

- Line speed – up to 900 m/min (code and substrate dependent)

- Maximum laser output power at lens – 30 W

- Lens and head options (range):

- Spot Size 0.114 mm – 1.6 mm

- Marking Field 29 mm x 36 mm to 440 mm x 601 mm (wide web application)

- Mark distance 67 mm – 576 mm

- Number of lines of text – only limited by character size and marking field size

- Character height – up to marking field size

- Print rotation – 0-360°

- Marking head rotation – 0-360°

- Code options: date, time, static text, variable text, serial numbers, alphanumeric, shift codes, increment/decrement (batch count), ID Matrix 2D codes, barcodes, QR codes, graphics and logos, Julian dates, custom date and time formats

- Laser tube wavelengths – 10.6 µm, 9.3 µm, or 10.2 µm

- Marking head options – 4 marking heads available as standard

- Versatile Beam delivery options for easy integration into your production line:

- Down (90°) or Straight (0°) Shooter

- 360° Beam Extension Unit (BEU)

- Variable length Beam Turning Unit (BTU)

- IP rating – IP54 as standard, IP65 option

- Air cooled – not factory air

- Large volume gas tube can last in excess of 45,000* hours

- Laser tube warranty – 2 years

- *Tube life may vary according to application.

Linx CSL60

60W - Flexible solution for high-speed retail coding

Applications & Materials

Materials support incl. Glass, Rubber | For harsh environments | Barcodes | Batch coding | Data Matrix & QR codes | Up to 900m/min | Print unlimited lines of text

The Linx CSL60 Laser System marks complex codes at a high resolution onto high-speed lines. The 60 W laser power combined with a powerful processor allows coding onto hard to mark materials such as glass and rubber. Full system IP65 rating makes it a reliable coding solution for harsh production environments such as beverage, automotive or extrusion.

Key benefits

Easy to use

Meet production targets

Print in more applications

- Easy message creation and management of printing parameters with the large colour LinxVision® Touch Screen, and LinxVision software

- Easy line integration – detachable marking head with quick disconnect cables

- Multiple beam delivery options allow for coding in any orientation

- Reduce your coding errors and meet coding regulations with password controls that can restrict access to qualified personnel only

- Remote connectivity to access, monitor and control Linx CSL laser coders and receive remote technical support with Linx PrinterNet, a secure, cloud-based service

- A powerful, four-core processor allows printing of complex messages – including 2d barcodes, QR codes and logos – on fast lines with no compromise on code quality

- Code up to 70,000 bottles per hour*

- Reduce running costs and delays with 45,000* hour tube life – one of the longest on the market

- Service intervals typically twice that of the industry standard

- No expensive factory air for cooling

- High power 60 W laser tube for coding onto hard materials such as glass, rubber and HDPE

- Over 20,000 different configurations to economically meet your coding requirements

- Wide web applications for large area coding or multiple lines of products

- Crisp, clear coding onto cold glass bottling lines, at high speed, with VisiCode®, a unique set of parameters

- Flip, mirror or curve text – easily code onto difficult shapes

*tube life and line speed are application dependent

Technical Specifications

Coding and marking capability

- 60 W CO2 scribing laser coder

- Line speed – code up to 2100 characters/second; 70,000 bottles/hour; 900m/min

- Maximum code height – 601mm

- Marking field size – up to 440 mm x 601 mm

- Laser wavelength – 9.3 μm or 10.2 μm or 10.6 μm

- Laser tube warranty – 2 years

- Spot size – from 0.091 mm to 1.65 mm

- Print rotation – up to 360°

- Marking head rotation – up to 360°

- Code options – Date, time, static text, variable text, serial numbers, shift codes, increment/decrement (batch count), 1D/2D barcodes, graphics and logos, Julian date, Custom date and time formats, 2D codes including DotCode.

- IP rating – full system IP65 rated as option; IP54 as standard.

- Air cooled for both IP54 and IP65 variants.

Linx SL1

10 W Compact Laser Coder

The Linx SL1 is a compact, cost effective coder designed to fit easily into production environments where space is constrained. An ultra-fast mirror system enables faster coding than other lasers in its class, while using much less laser energy but delivering 20% more power. No routine servicing or consumables mean the lifetime costs of the Linx SL1 laser are favourable compared to other types of printer, with no variable costs.

Key benefits

- Affordable laser coding – no consumables or routine servicing

- Designed to deliver enhanced reliability

- Longer operating lifetime than equivalent lasers

- Mix text, logos and machine-readable codes in a single message

- Wide range of fonts to compliment packaging design and branding

- Easy installation into tight production lines

- Supports 2D code standards including QR and dot matrix codes

- Wider range of marking fields than equivalent laser coders

Technical Specifications

Software

Linx Draw

System Configuration

- Ethernet (TCP/IP, 100Mbit LAN), RS232, digital I/Os

- Inputs for encoders and product detector triggers

- I/Os for the signals, start, stop, error, job select (32 different templates), trigger, encoder, ready to mark, marking, shutter closed and machine/user interlocks

- Graphics-orientated user interface for intuitive and fast preparation of complete code templates on PCs

- Text/data/graphics/editor

- Configurable in several languages

- Easy access to standard CAD and graphic programs via import functions

- WYSIWYG

- Password-protected security levels

Technical Data

- Sealed CO2 laser, power class 10W

- Laser wavelength – 6 μm, 4 focusing lenses

- Laser class – 4 (according to IEC 60825-1:2007)

- Languages – English, French, German, Dutch, Spanish, Portuguese, Chinese

- Options – Beam shield, Exhaust unit, Product detector, Encoder, Stand, dual interlock safety module, Controller

- Standard – Start and stop keys with safety switch

- LED indicators for status, laser emission, error

- Electrical requirements 100 – 120V, 200 – 240V, Autorange 1PH, 350 VA, 50/60 Hz

- Cooling – internally air-cooled

- Ambient temperature – 5 – 35ºC

- Humidity range – 10 – 90 %, non-condensing

- Weight -marking unit approx. 12.5 kg

- Enclosure – stainless steel

Marking Formats

- Standard fonts (Windows® TrueType®/TTF; PostScript®/PFA, PFB; OpenType®/OTF)

- Individual fonts such as high-speed or OCR

- Machine-readable codes: Bar codes: BC25,BC25I, BC39, BC93, EAN 8, EAN 13, BC128, EAN 128,

- Postnet, SCC14, UPC_A, UPC_E, RSS14TR, RSS14ST, RSS14STO, RSSLIM, RSSEXP

- Data matrix 2D codes: ECCOOO, ECC050, ECC080, ECC100, ECC140, ECC200, ECC PLAIN, QR

- Graphics/graphic components, logos, symbols, etc. (the most common file formats such as DXF, JPG, AI can be imported)

- Linear, circular, angular text marking; rotation, reflection, expansion, compression of marking contents

- Sequence & serial numbering; automatic date, layer, time coding, real-time clock; online coding of Individual data (weight, contents, etc.)

Linx Fibre Lasers

Linx FSL20 & FSL50

Fibre laser technology for permanent coding on a wide range of materials

Permanently mark on a wide range of materials, including metal, rubber, plastic, and packaging foils. Very fine spot size creates excellent quality codes and makes Linx Fibre lasers ideal for marking very small components, or large amounts of information onto small areas. Text, machine readable codes, graphics and logos are all marked with extreme clarity for traceability; ideal for pharmaceutical, medical devices, automotive and electronics industries, as well as FMCG packaging.

Key benefits

- Laser tube life of over 100,000 hours – less downtime

- Fine spot size for high quality codes

- Two beam orientation options allows coding in any direction

- Choice of 4 lenses for codes tailored to your requirements

- Compact marking head for easy integration into moving and static lines

- Internal air cooling system for increased efficiency and less maintenance

- Quick message creation reduces time spent on setup and changeovers

- Extremely efficient use of the laser with no compromise on code quality or speed

Technical Specifications

Marking Formats

Performance

Physical Characteristics

- Standard fonts (Windows® TrueType®/TTF; PostScript®/PFA, PFB; OpenType®/OTF) ·

- Individual fonts such as high-speed or OCR ·

- Machine-readable codes: Bar codes: BC25,BC25I, BC39, BC93, EAN 8, EAN 13, BC128, EAN 128,Postnet, SCC14, UPC_A, UPC_E, RSS14TR, RSS14ST, RSS14STO, RSSLIM, RSSEXP Data matrix 2D codes: ECCOOO, ECC050, ECC080, ECC100, ECC140, ECC200, ECC PLAIN, QR ·

- Graphics/graphic components, logos, symbols, etc. (the most common file formats such as DXF, JPG,AI can be imported) ·

- Linear, circular, angular text marking; rotation, reflection, expansion, compression of marking contents ·

- Sequence & serial numbering; automatic date, layer, time coding, real-time clock; online coding of individual data (weight, contents, etc.)

- Line speed – 1 to 6,000 mm/s (typical). ·

- No of lines of text – Only limited by character size and marking field ·

- Character height – Up to marking field ·

- Print rotation – 0- 360 degrees ·

- Operation mode – pulsed (Q switch)

- Material – Painted sheet metal housing ·

- Weight: marking unit/supply unit – 8kg / 19kg ·

- Laser head – IP54 ·

- Conduit length – 2.7m ·

- Minimum bend radius of conduit – 90 mm ·

- Head mounting options – 90-degree (standard) and straight-out (option) ·

- Cooling system – Air cooled with automatic overheat detection ·

- Supply voltage / frequency – Auto selection range 100 to 240 V / 50/60 Hz (auto range) ·

- Maximum power consumption – 500 VA ·

- Operating temperature range -10 – 40° C ambient ·

- Humidity range – 10% to 90% relative humidity, non-condensing

Communication

- Ethernet, TCP/IP and RS232, digital I/Os ·

- Inputs for encoders and product detector triggers ·

- I/Os for start, stop, external error, job select, trigger, trigger enable, encoder, system ready, ready to mark, marking, shutter closed, error, bad, good signals and machine/ operator interlocks

Linx SLHP

Superior quality codes at some of the fastest speeds available on the market.

The Linx SLHP is a high power, 120 W CO2 laser which can code accurately at high speeds – for example in excess of 70,000 bottles per hour on high speed beverage production lines. The high power allows many different materials to be marked quickly and permanently –including traditionally hard-to-mark substrates such as glass, rubber and PET.

Key benefits

- Graphics can be accurately reproduced with vector-generated codes

- High power of the laser means a shorter dwell time on the product

- Air-cooled – no factory air required

- Large scan area for multiple lines of code/graphics

- IP56 rating ensures reliable operation in harsh production environments

- Internal air cooling system for increased efficiency and less maintenance

- Air-cooled – no factory air or water required

- Efficient use of the laser source prolongs the life of the laser tube

- No ongoing consumable costs

Technical Specifications

Marking Formats

- High quality codes

- Large area marking capability

- Simple alphanumeric codes

- Multi-line codes

- GS1

- Bar codes

- 2D Data Matrix

- Accurate reproduction of complex graphics, logos, symbols

Applications

- Static and ‘on the fly’ coding

- High speed beverage lines on glass, plastic and labels

- High speed and complex pharmaceutical coding

- Anti-counterfeiting e.g automotive, high value perfumes/spirits, tobacco

- Wide range of materials including rubber, glass, PET, PVC

Software

- Comprehensive and versatile

- Multiple EU display languages included

- Time/date stamp

- Incremental fields

- Text orientation

- 3 level password protection

- 2 channel quad encoder input

- Flash memory backup

- RS232 interface

- Windows® operating system

Physical Characteristics

- Laser – single sealed CO2

- Average coding power – 120 watts

- Beam delivery – 7 knuckle articulated arm for optimal integration

- IP rating – IP56 marking head and supply unit

- Cooling – Integral air cooling; water cooled option for high duty applications

- Supply voltage – 200-240v 50/60 Hz Single or Bi-phase

- Integral QWERTY keypad; remote keypad option

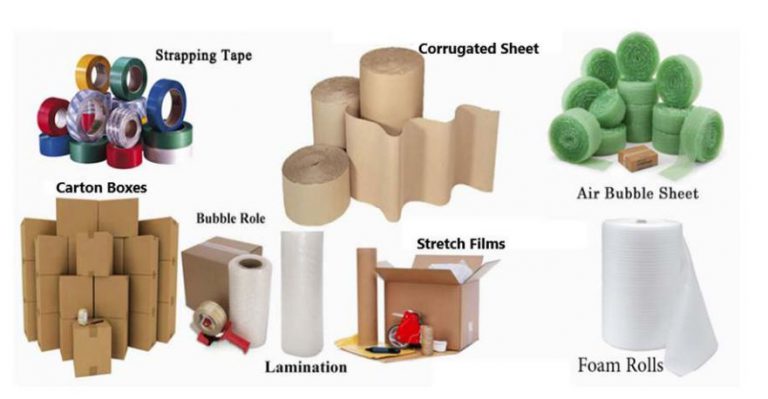

PACKAGING MATERIALS

Stretch Films

Laminations

Packaging Tapes

The most common stretch wrap material linear low-density polyethylene or LLDPE, which is produced by copolymerization of ethylene with alpha-olefins, the most common of which are butene, hexene and octene.

General Laminated Film is made of multiple raw material layers with barrier properties that are chosen depending on the customer’s needs. With its increased efficiency, General Laminated Film is widely used in high speed production for flexible packaging because of several advantages

It is important for companies using packing tape to choose the proper tape and strength when deciding a tape to seal their cartons and boxes. The wrong choice of tape can cost companies money, time, and disrupt efficiency. Common terms used to help describe tape are listed below.

a) Tensile Strength

b) Backing Material

c) Elongation